Shenghong fine powder grinding mill Load Controller, automatically measure the working current of the grinding mill and compare with the setting parameters, and then adjust the inverter output frequency to change the actual input variable (feeding amount), stabilize the load of the grinding mill; or directly adjust manually the load of the mill enables the fine powder grinding mill to be in an optimal load state, improve the operating efficiency of the motor, and avoid the occurrence of blockage. The controller is Automatic, low price and low maintenance.

Shenghong fine powder grinding mill adopts 128*64 blue screen white character highlight LCD display interface, micro switch button, 96*96*100 instrument box, easy to install, intuitive display and simple operation. The controller has 2 DC4-20ma outputs, 1 AC0-5A input, and 4DI input 4DO output port. The input and output are all optically isolated and have strong anti-interference ability.

The load controller adopts integrated grading impeller speed regulation, which is suitable for ordinary positive and negative grinding mill, grinding mill, and mill with linear motor feed gate feeders.Integrate multiple auxiliary detection functions.

Function introduction

control mode

Manual/automatic switching (the control output does not change during the switching process) to ensure continuity of the production process.

Alarm alert function

When the current is at no-load/overload time exceeds the set value, the controller will give an audible and visual alarm, prompting the operator to proceed to the next step according to the operating state of the device, and pressing the stop button to cancel the alarm.

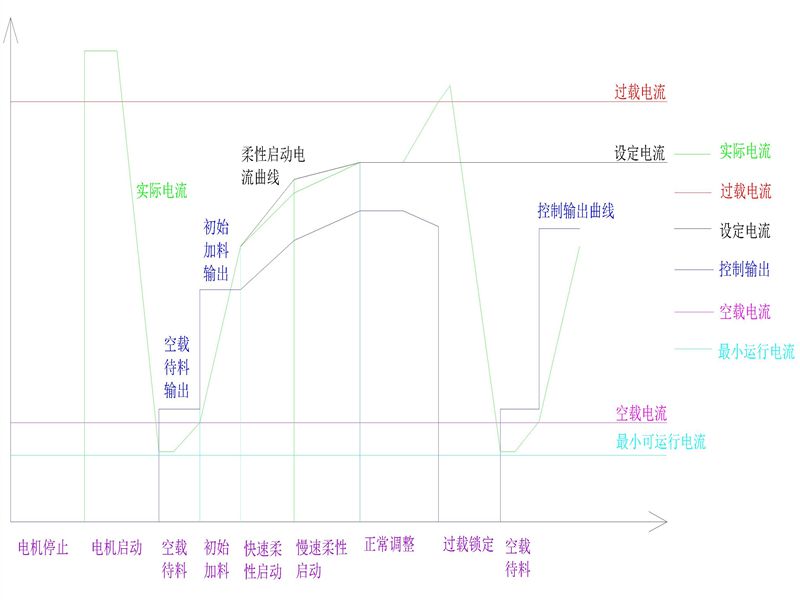

Work status

Motor stop, current too low, no load waiting, initial lock, quick start, slow start, normal operation, overload lock, pause output.

Running timing function

Automatically record the motor and display cumulative running time, dead time, single running time and dead time, and accurate to the second, providing basis for equipment management and production management.

選型指導(dǎo)(圖)

型號 |

P2B-I-20 |

P2B-I2-20 |

P2B-I-20-8 |

喂料電機(jī)控制 |

有 |

有 |

有 |

分級葉輪控制 |

無 |

有 |

無 |

粉碎機(jī)風(fēng)壓檢測 |

無 |

無 |

有 |

正反轉(zhuǎn)檢測 |

有 |

無 |

有 |

運(yùn)行計(jì)時(shí) |

有 |

有 |

有 |

空載計(jì)時(shí) |

有 |

有 |

有 |

直線電機(jī)驅(qū)動 |

無 |

無 |

有 |

變頻器報(bào)警檢測 |

有 |

有 |

有 |

DA |

4-20MA |

2組4-20MA |

4-20MA |

AD |

0-5A |

0-5A |

0-5A |

喂料門開度控制 |

無 |

無 |

有 |

適用范圍 |

普通正反轉(zhuǎn)粉碎機(jī) |

帶分級葉輪超微粉碎機(jī) |

帶直線電機(jī)喂料門控制粉碎機(jī)(布勒粉碎機(jī)) |

天白云13880&site=cntaobao&s=1&charset=utf-8)